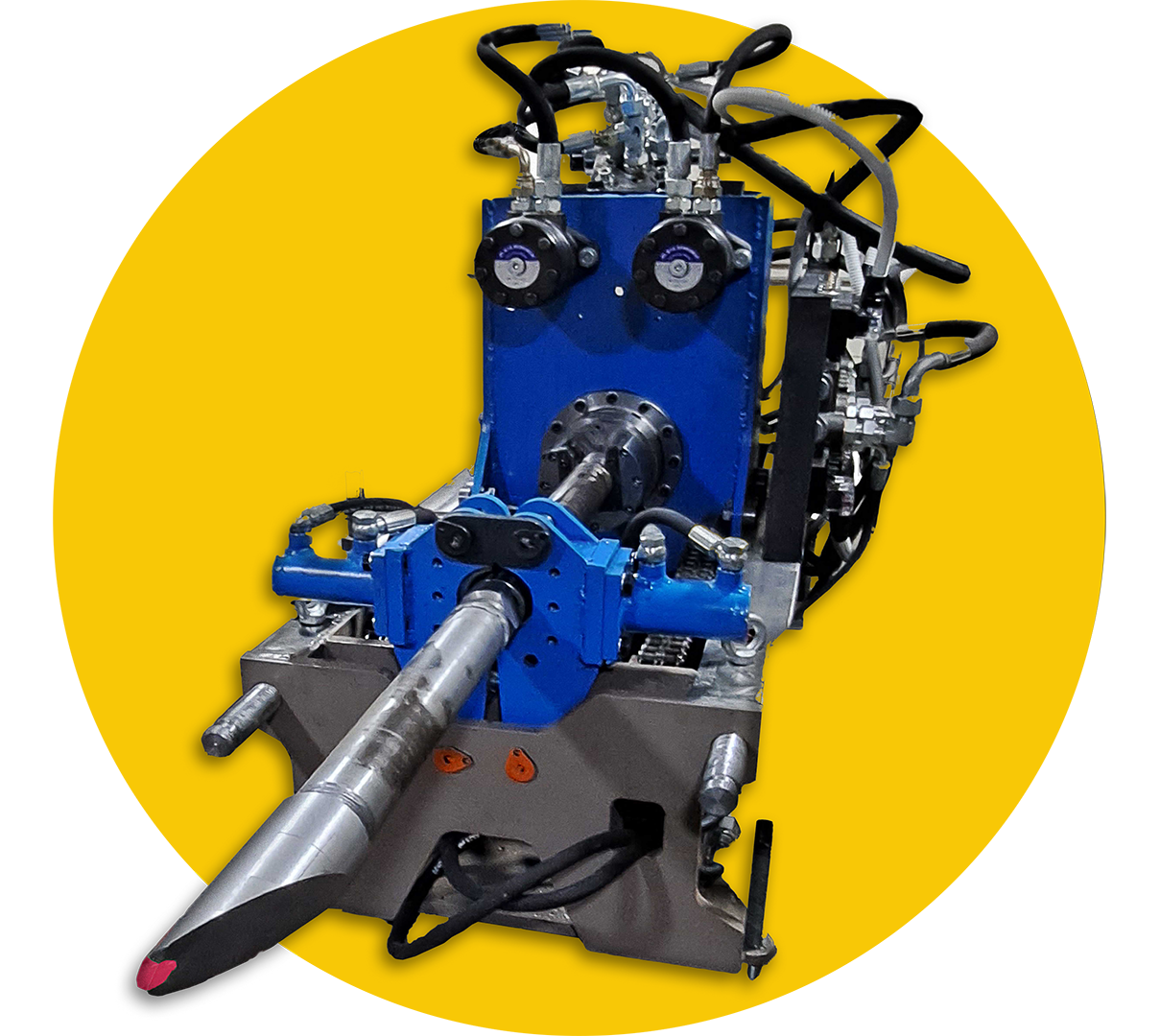

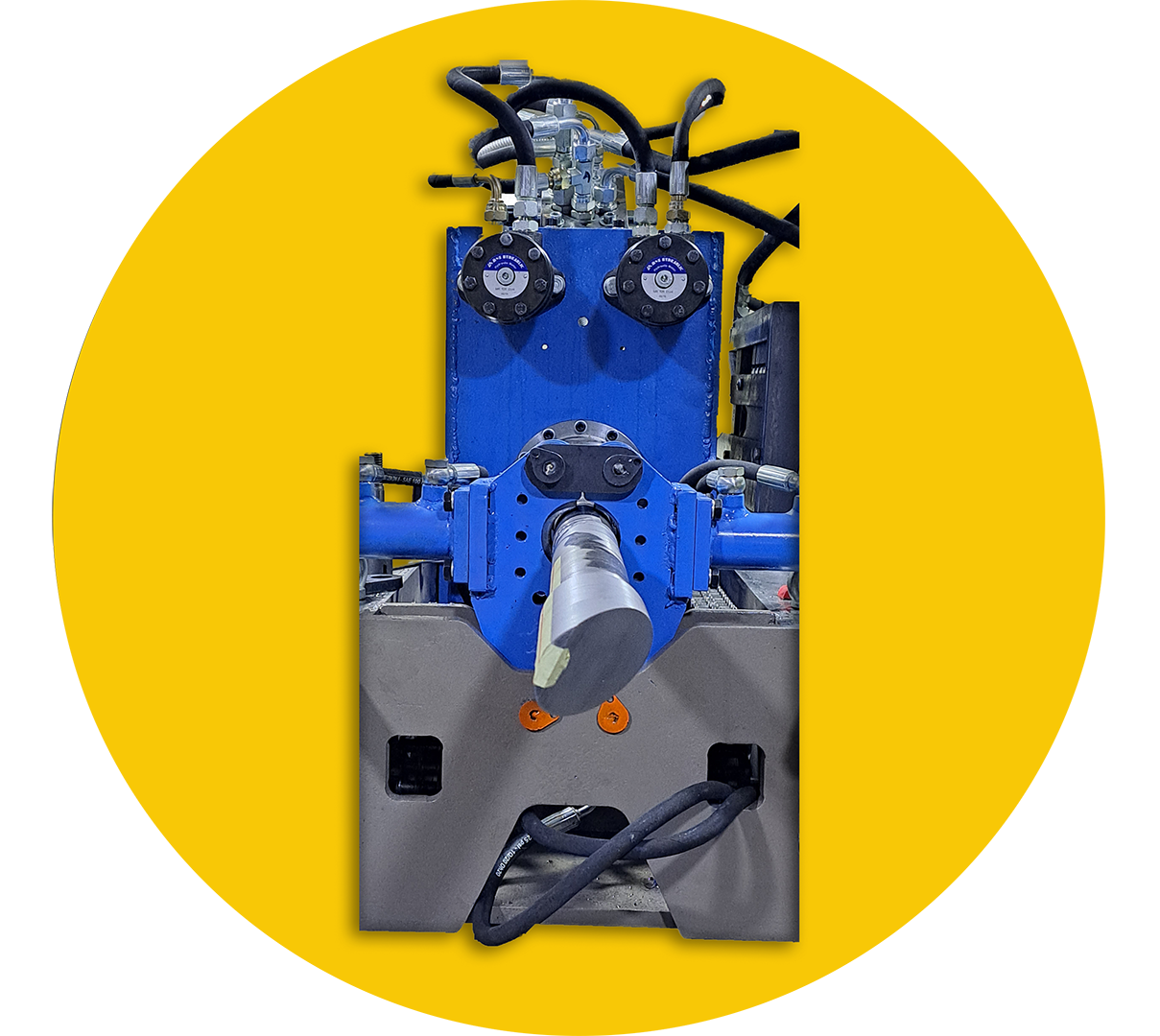

maxi M is a compact, sensor-guided trenchless drilling robot purpose-built for last-mile underground utilities. It unites a powerful mechanical platform with an intelligent guidance unit and an intuitive operator interface—transforming precise horizontal drilling into a repeatable, data-driven workflow rather than an artisan skill limited to a few specialists. The development of Drilltek is proudly supported by the national Government Innovation Fund.

Small footprint. Big performance. lengths up to 45 m

Works as HDD or precision-guided—your choice based on project needs

Zero guesswork. Zero specialized skills.

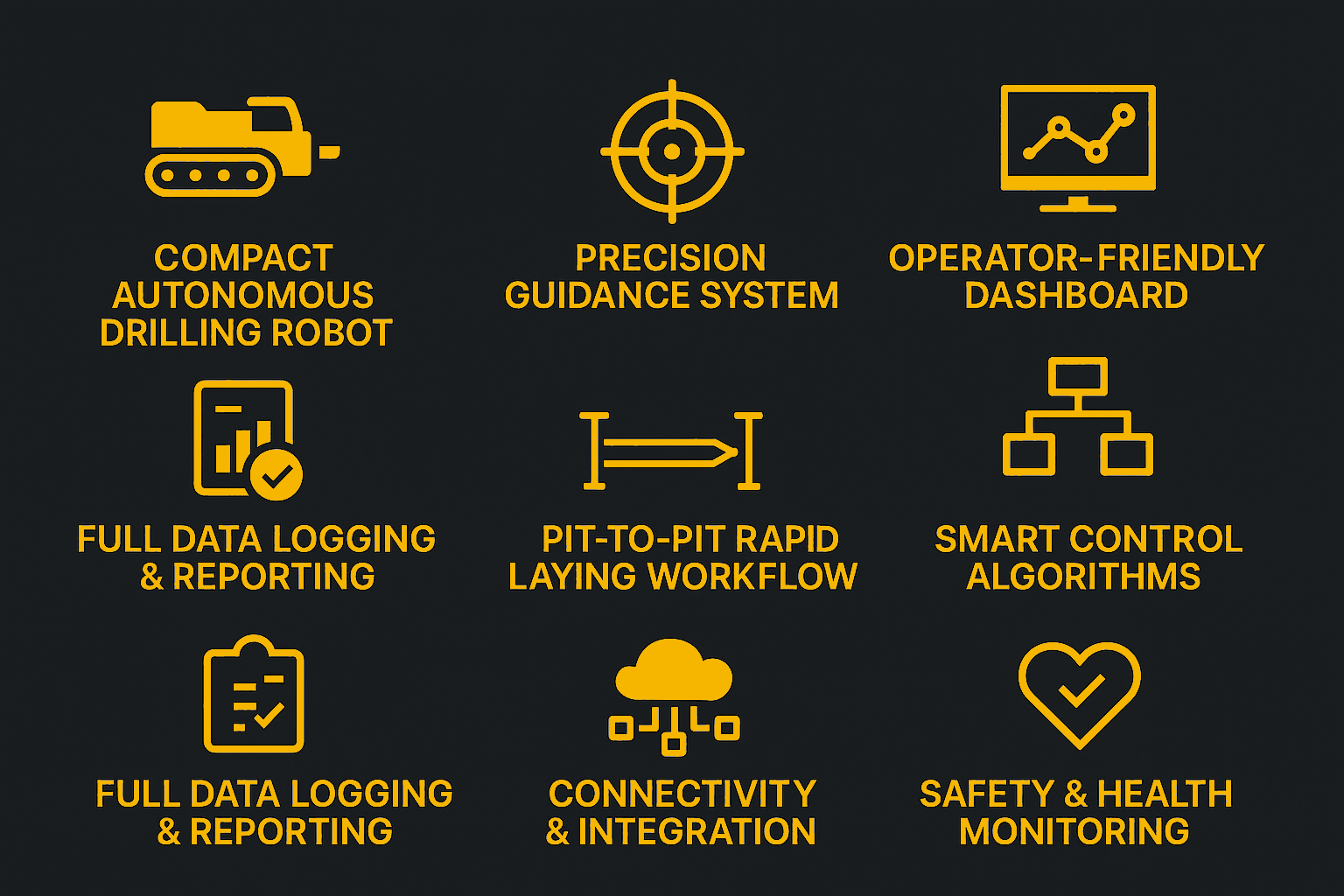

Live attitude indicator, sensor gauges, torque charts, and

system health in one clean interface.

The machine thinks ahead.

Torque, thrust, path correction, and safety all managed automatically.

Every meter documented.

Exportable logs, QA/QC reports, and digital-twin ready datasets.

Short bores. Fast builds.

Modular installation method that beats open-cut in speed and cost.

Built for the smart city ecosystem.

Underground mapping, cloud export, GIS/BIM compatibility.

Protection built in.

Thermals, comms, torque, alignment, and emergency-stop logic.

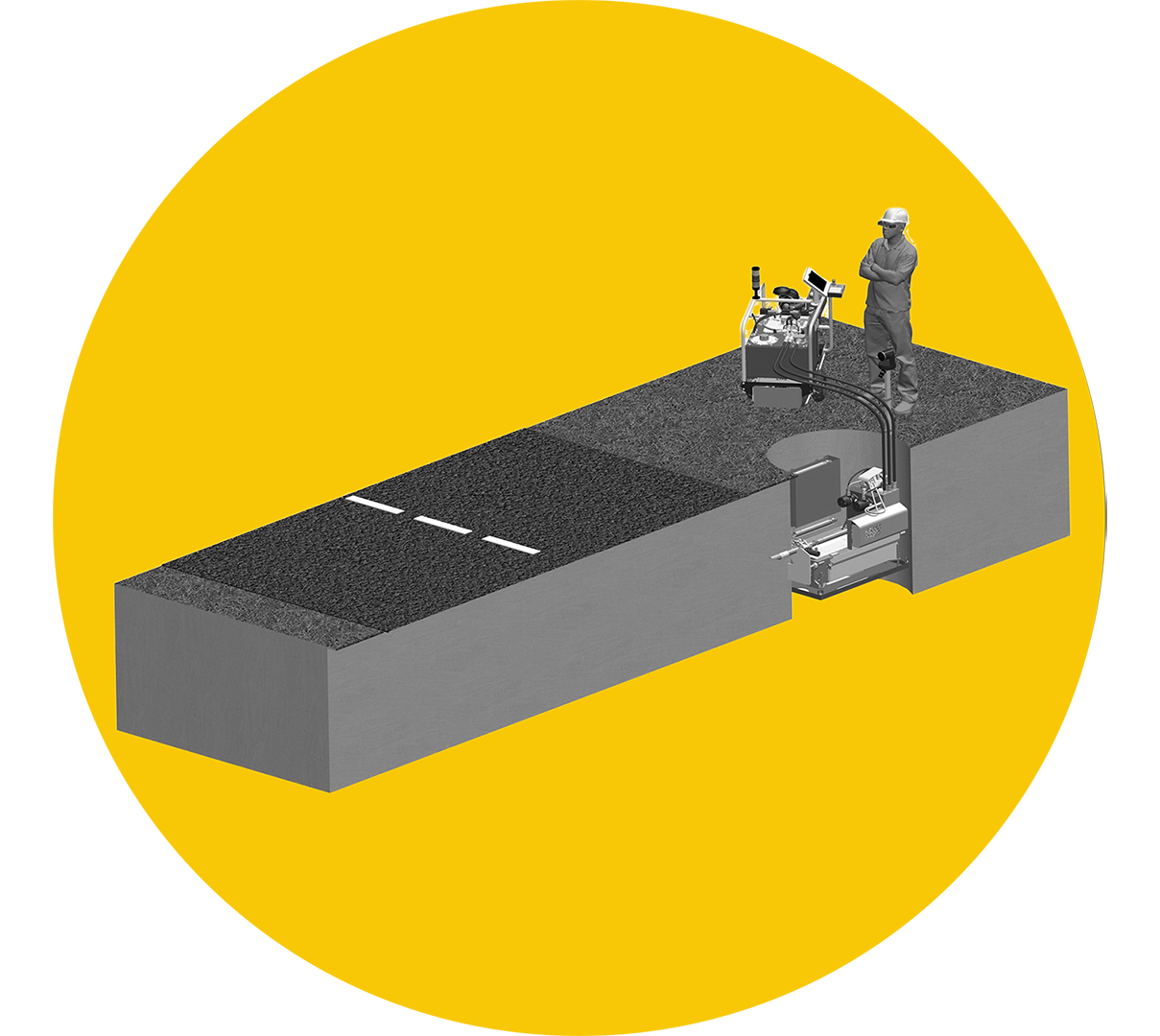

Circular or rectangular man pits are created at intersections, building fronts, or utility connection points—requiring minimal excavation. "Ideal in combination with a small mobile vacuum excavation unit (VAC)"

maxiM autonomous system performs precise horizontal drilling between an entry pit and an exit point with aircraft-level accuracy.

Instead of long bores, multiple small pits are opened along the planned route. The Drilltek robot drills short, precise boreholes between each pit, creating a modular underground network.

Conventional trenchless machines excel at long, large-diameter installations, but the compact or high-accuracy alternatives carry heavy setup time and cost burdens—rendering them uncompetitive for short, last-mile utility segments.

These systems become:

As a result, in the short-distance, small-diameter, last-mile segment:

Open-cut dominates because:

Drilltek systems are engineered precisely for the operational space where efficiency, precision, and minimal disruption are paramount. We deliver unmatched value in challenging environments characterized by:

This is the exact operational space where Drilltek excels.